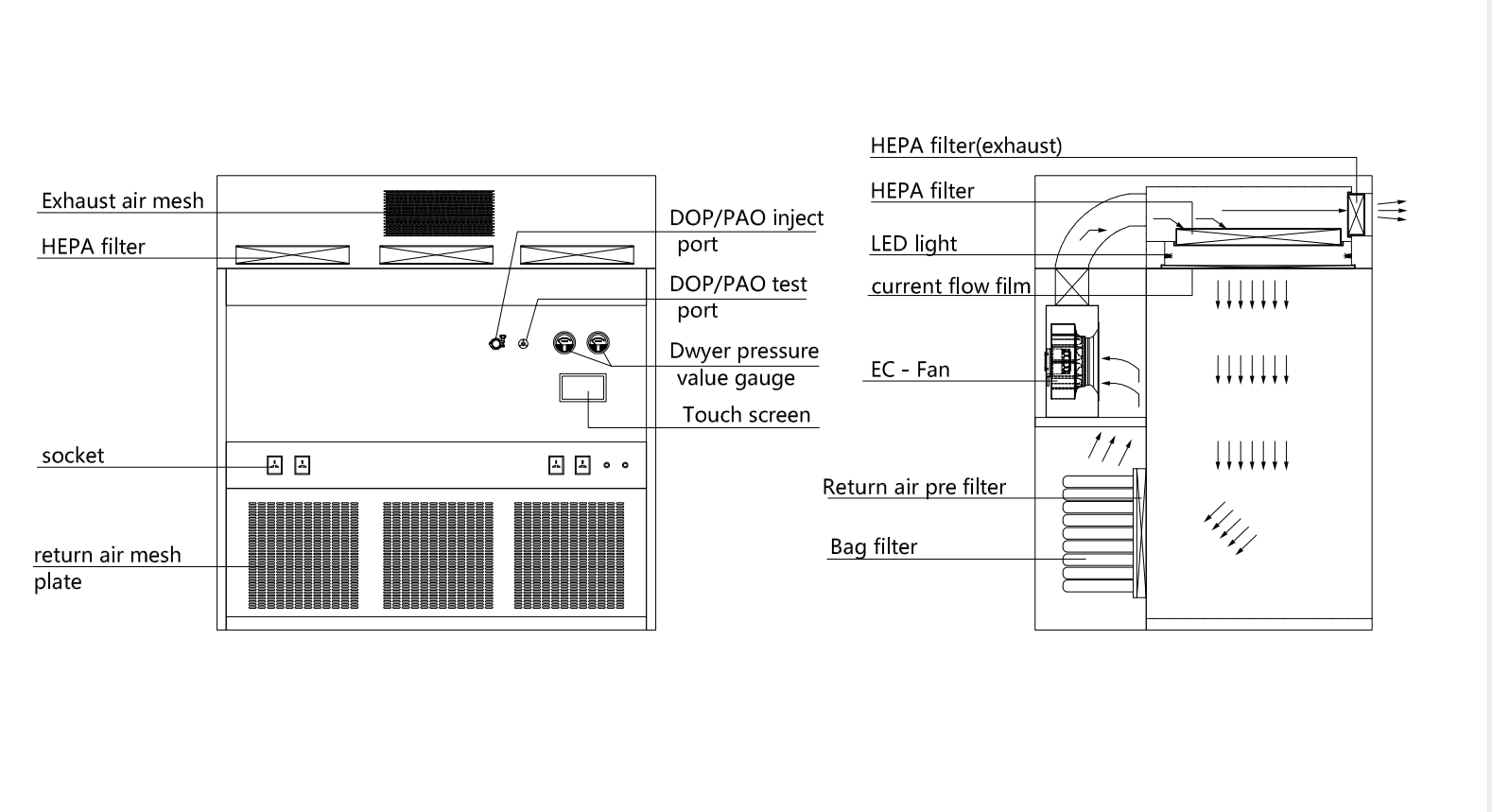

What is Sampling/dispensing booth?

The dispensing booth is also called a pharmaceutical sampling booth and pharmaceutical weighing booth,downflow booth or powder containment booth.

Dispensing booth is a kind of laminar flow filtration clean room equipment which is employed in dispensing, sampling and weighing of powders and chemicals in pharma, biotech and chemical industries.