There are severl difference between clean bench & Bioasafety cabinet

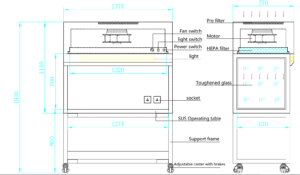

The clean bench ensures that the work surface is constantly flooded with HEPA-filtered air in a laminar flow. It is in a positive environment.

The clean bench protects the work on the work surface, but not personnel or the surrounding environment from aerosols created on the work surface.

The Clean bench do not provide any protection to the worker. They are designed to provide a sterile environment to protect the product. Air potentially contaminated with infectious agents may be blown towards the worker.

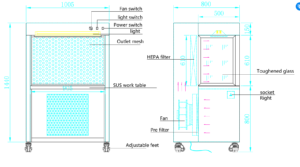

Biosafety cabinets protect the product as well as the user and the environment. They operate under negative air pressure , protecting the user from exposure to aerosolized infectious agents. The air sucked into the hood is sterilized by high efficiency particulate air (HEPA) filtration before being exhausted out, thereby protecting the environment.

Biosafety Cabinets are similar to the Laminar Air Flow cabinets. They too contain HEPA filters but there is one dissimilarity that Biosafety Cabinets offers complete protection to the users against harmful pathogens, since the contaminated air is filtered before it can come in contact with the users.