What is Fan Filter Unit?

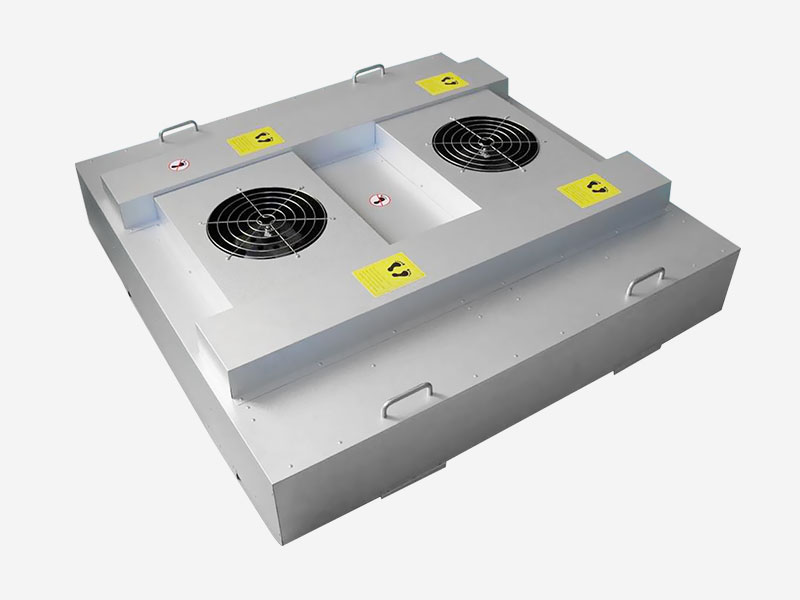

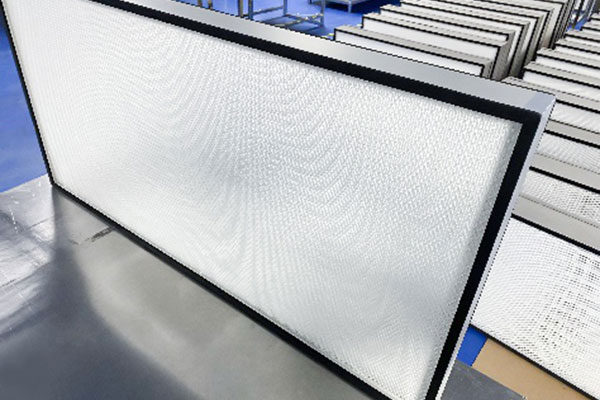

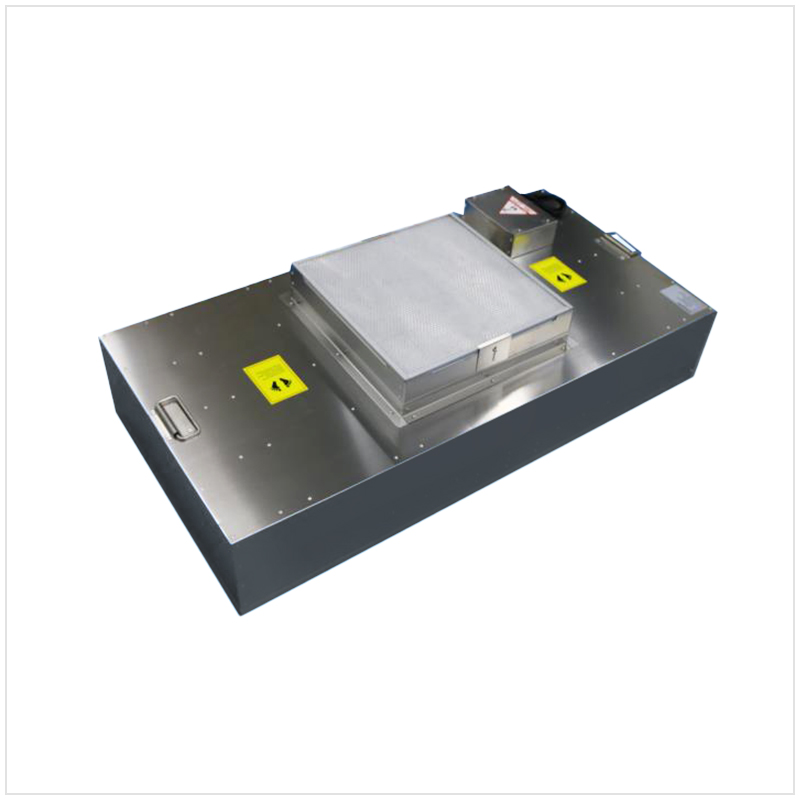

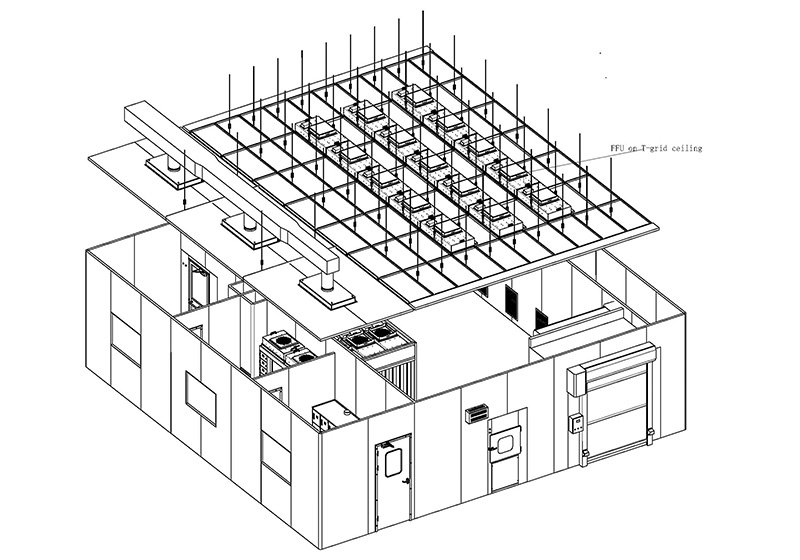

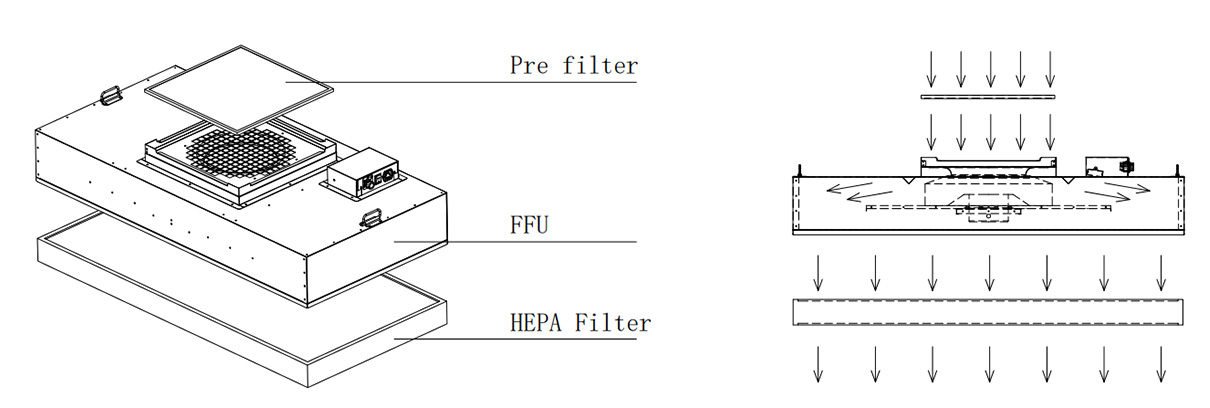

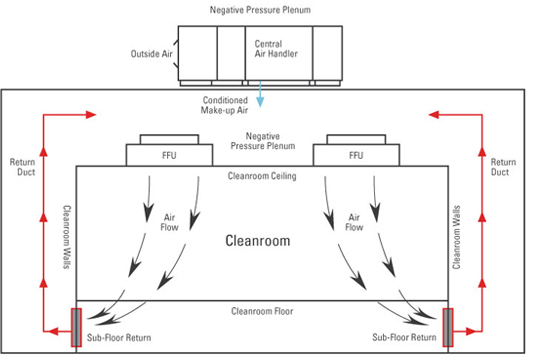

A Fan Filter Unit (FFU) is a self-contained air filtration device used in cleanroom environments to provide high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filtration. It consists of a fan, a filter, and a diffuser panel, all housed within a single unit.

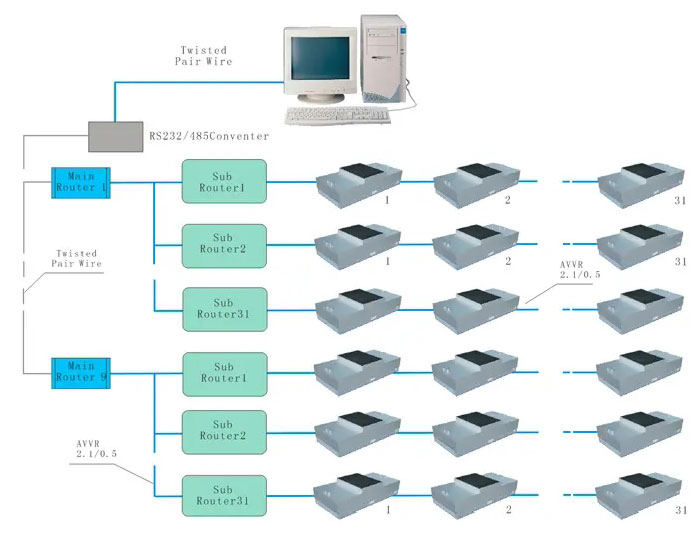

FFUs are flexible and economic solutions to remove particles from the recirculated air of turbulent or unidirectional ventilated cleanrooms.