Cleanroom Equipment for

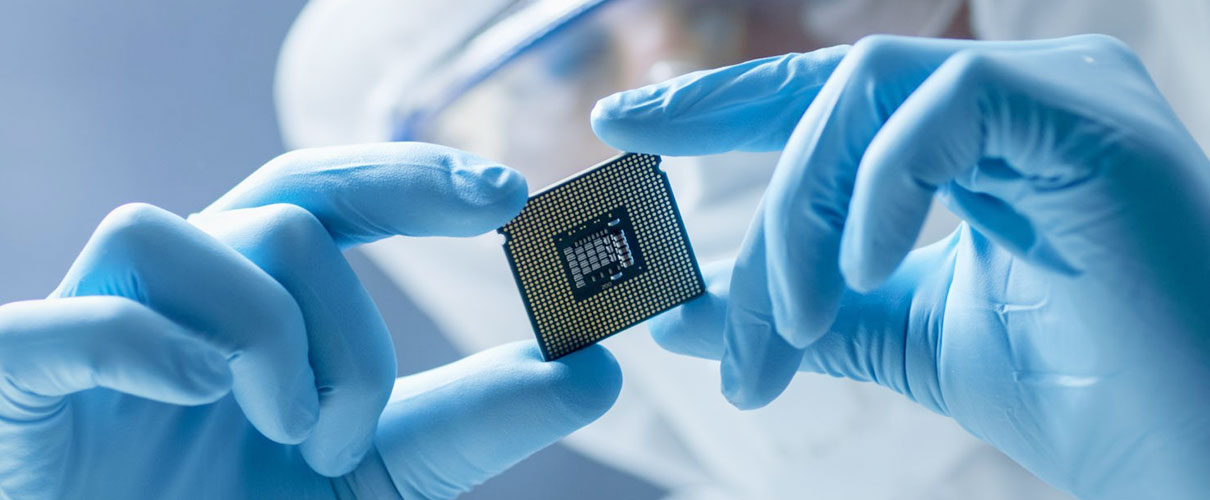

A semiconductor fab is a manufacturing plant in which raw silicon wafers are turned into integrated circuits. Photolithography is a common manufacturing process inside of the cleanroom. This process involves photographing the circuit pattern on a photosensitive substrate and chemically etching away the background. Types of chips manufactured in a semiconductor fab are NAND flash, DRAM for memory, microprocessor, graphics controller, hard drive controller, and RAID controller.

Once completed, these chips go into a wide range of devices such as computers, mobile phones, televisions, laptops, drones, military equipment, and automobiles.

Why semiconductor manufacturing processes need cleanroom?

Most semiconductor manufacturing processes require cleanrooms that comply with ISO Class 5 or higher.

Semiconductor cleanroom environments must be engineered to control static, particulate matter, outgassing, and other sources of contamination and compromising conditions. Environmental control is critical and maintaining the required levels of air purity is a non-negotiable for the total performance of the cleanroom. To help maintain air purity, fabs utilize filters at the ambient air inlet (make-up air handler, MUA), often in the return air handlers (RAH) and on top of cleanroom ceiling fan filter units (FFU).

We offer air filters and cleanroom equipment (FFU, Air shower, pass box, etc) designed to meet the specifications for all classes of cleanrooms, from ISO Class 1 through ISO Class 9