How to choose FFU for your cleanroom

1. Application

Where it is applied, laboratories, medical facilities or microenvironments?

FFUs are widely used in laboratories, medical facilities, or microenvironments by removing harmful airborne particles from recirculating air. Large cleanrooms require a proportionally large number of FFUs. Depending on the cleanliness requirements of the controlled space, more fan filter units can be added to the grid in order to meet ISO standards for airflow velocity and air changes per hour. As FFUs require space above the ceiling grid, plenums are commonly used for clean rooms with height restrictions.

2. FFU Construction

- Negative pressure or positive pressure

- Standard Pre filter+FFU frame+HEPA filter

- Customized: Without pre filter+FFU frame+ULPA filter

- FFU with room side replaceable HEPA filter

- FFU with collar flange on top

- FFU with insulation

- FFU with Wall-mounted separate control box

3. FFU Frame Material

Al-zinc plate /Gi plate Fan Filter Units

It is the most common material for standard FFU. The smooth surface is easy to wipe down, Light-weight, and low-cost

Powder-Coated plate Fan Filter Units

Powder-coated steel is an economical choice that also provides favorable heat and chemical resistance for most applications.

white powder coat finish provides a high-quality, durable barrier to protect against corrosion, plus a clean and attractive aesthetic. The advanced heat-fuse formulation can resist chipping, scratching, fading, and wearing.

Stainless Steel 201/304/316 plate Fan Filter Units

Stainless steel is an optimum standard among cleanroom construction materials in biopharmaceutical, lab, and medical GMP facilities environments. Easy cleaning, favorable heat properties, and chemical resistance; The smooth surface is easy to wipe down, resists biofilm buildup, and will not off-gas.

4. FFU sizes

Standard FFU ((2′ x 2′, 2′ X 4′)

24″ x 24″ Fan Filter Units

2′ x 2′ fan filters provide moderate flow rates and accommodate standard square ceiling grid installations. Lightweight (25KG) provides easier installation.

24″ x 48″ Fan Filter Units

2′ X 4′ fan filter units accommodate standard cleanroom ceiling grid and laminar flow hood configurations and are intended for use with supported ceilings that can safely bear the weight of a fan filter unit or light panels to be installed. Uniform flow of micro-filtered air to meet cleanliness standards from Class 10 (ISO 4) to class10000. eyebolts in all (4) corners for hang wire support.

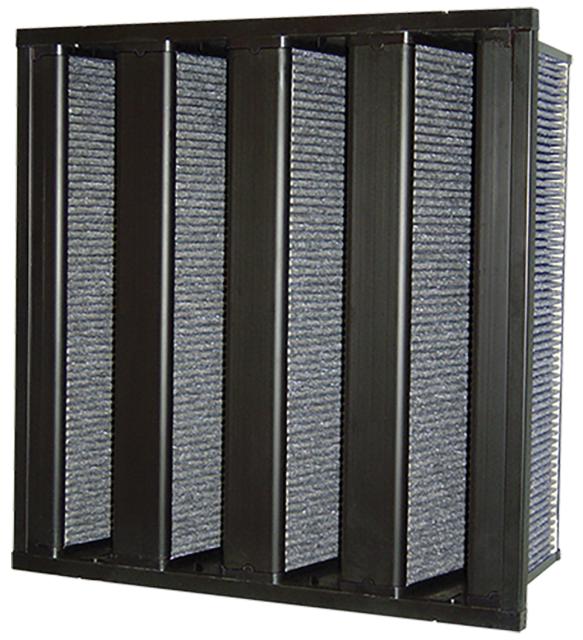

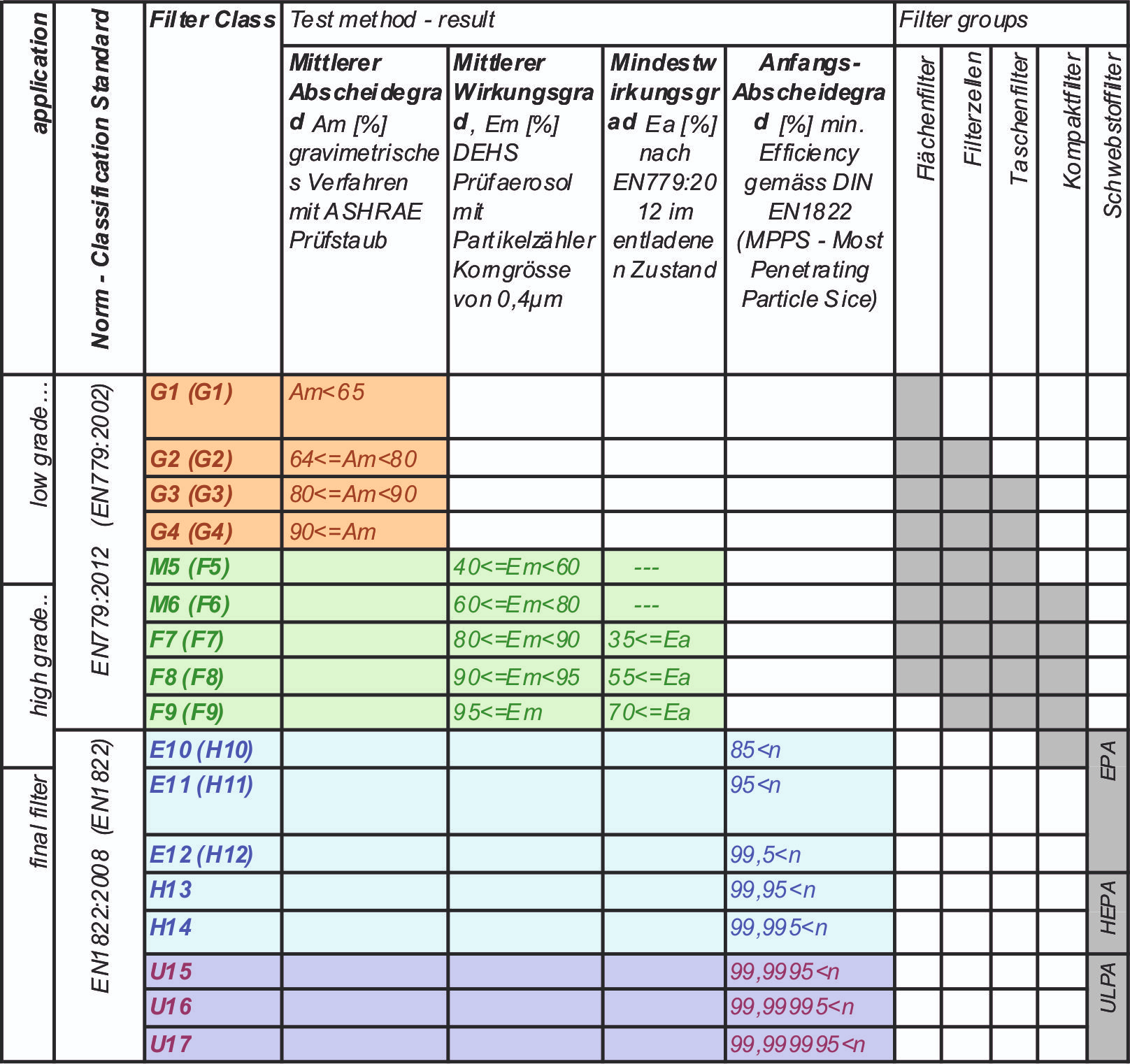

5. HEPA /ULPA Filters

HEPA Filter

HEPA filters remove 99.97% of airborne particles greater than or equal to 0.3μm in diameter. HEPA filters are common for contamination and air quality control for industries including pharmaceuticals, medical devices, OEM assembly, healthcare, life sciences, infection control, and laboratory or testing environments.

ULPA Fan Filter Units

ULPA filters are 99.999% efficient for monodispersed particles 0.12 μm in diameter or larger. ULPA filtration offers additional particulate control for ultra-sensitive hardware including display panels, wafer chips, micro-optics, satellite imaging, and nanotechnology applications.

6. Motor type (AC/EC)

Electronically commutated (EC) brushless motors/EBM

AC

7. Speed controller

- 3-Step speed controller &9-step speed controller

- Step-less speed controller Group control

- LCD display Panels connect to EC FFUs for individual or centralized grouped control and remote monitoring of room differential pressure, particle counts, temperature, and humidity. The system offers advanced control for up to 10 sets of FFU to hundreds even thousands of FFU and 16 independently controlled cleanrooms.