How Pass Through /Pass Boxes Work ?

How pass through /pass boxes work and why they’re vital for cleanroom operations. Discover top applications across industries for cleanroom designers, contractors, and users.

🔍 Introduction: Why Cleanroom Efficiency Depends on Pass Through Boxes

In controlled environments like pharmaceutical cleanrooms, semiconductor facilities, and laboratories, even the smallest contaminant can ruin batches, delay production, or compromise safety. That’s where pass through boxes—also called pass through chambers or pass boxes—play a critical role. These devices are designed to transfer materials between spaces of different cleanliness levels without human entry.

For cleanroom designers, contractors, and end users, understanding how pass boxes work is key to optimizing workflows, minimizing contamination, and ensuring compliance with ISO and GMP standards.

⚙️ How Pass Through Boxes Work: The Inner Mechanism

A pass through box is essentially a sealed chamber with two doors—each accessible from opposite sides of a wall between clean and less-clean areas. The core principle: never allow both doors to open at once.

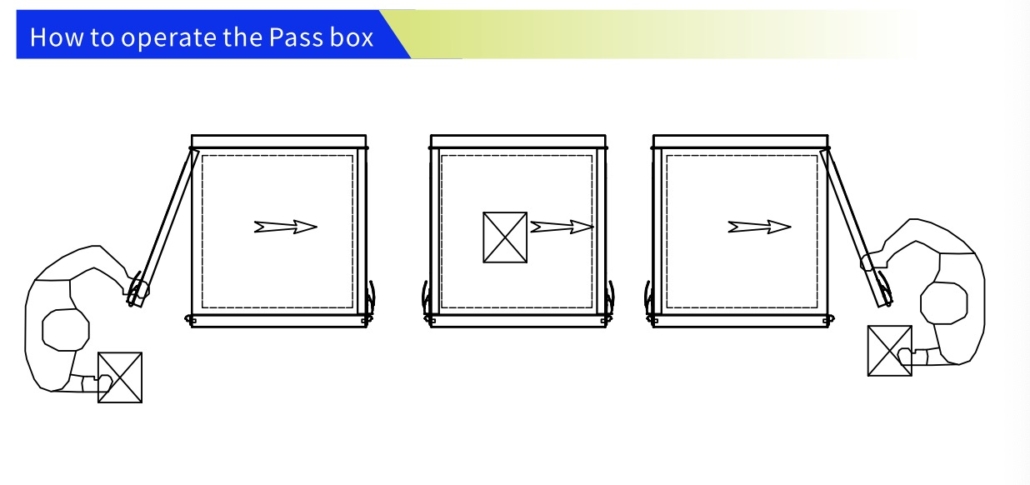

How to operate the passbox

Step-by-Step Process:

-

-

-

Item Placement

The operator on the non-cleanroom side places the material inside the pass box. -

First Door Locks Automatically

Once the door is closed, an electromagnetic interlocking system prevents it from reopening until the other door is closed. -

Optional Sterilization or Air Purging

Depending on the model, UV lamps may sterilize the interior or filtered air (via HEPA) may purge the air inside. -

Second Door Access

The cleanroom-side door unlocks, allowing the user to retrieve the item without cross-contamination. -

Automatic Reset

After removal, both doors reset and the system is ready for the next cycle.

-

-

Optional Features Include:

-

-

-

UV-C Lamps for microbial sterilization

-

HEPA Filters for particle-free air exchange

-

Audio/Visual Indicators for door status

-

Timers and Delays for added safety

-

-

🏭 Key Applications of Pass Through Boxes in Cleanroom Environments

Pass boxes are not one-size-fits-all—they vary by industry, environment, and regulation. Below are some of the most critical applications:

1. Pharmaceutical Manufacturing

Use: Transferring raw materials, packaging, or test samples between clean and support rooms.

Why It Matters: GMP regulations require strict material flow control. Pass boxes reduce human movement and maintain ISO Class 5-8 environments.

2. Electronics and Semiconductor Industry

Use: Moving delicate wafers or microelectronic components between fabrication areas.

Why It Matters: Eliminates particles that could damage circuits or reduce yields in Class 100 or better cleanrooms.

3. Biotechnology and Laboratories

Use: Safely moving biological samples, chemicals, or test results between labs.

Why It Matters: UV pass boxes help eliminate cross-contamination risks when handling sensitive materials.

4. Food & Beverage Production

Use: Transporting sterilized packaging, tools, or raw materials between controlled zones.

Why It Matters: Prevents microbial contamination while maintaining hygiene standards under HACCP guidelines.

5. Hospitals and Clean Healthcare Areas

Use: Transfer of medical equipment, sterile tools, and medication.

Why It Matters: Helps control hospital-acquired infections (HAIs) in operating rooms or sterile prep areas.

📐 Tips for Designers and Contractors

If you’re designing or installing a cleanroom, keep the following in mind when integrating pass through boxes:

-

-

-

Location is Everything: Position pass boxes near workflow intersections to reduce detours and traffic.

-

Match Cleanroom Class: Use dynamic or UV pass boxes in ISO Class 5+ areas.

-

Flush Mount Design: Choose models that sit flush in walls to prevent buildup of dust or bacteria.

-

Stainless Steel is Standard: Grade 304 or 316 steel is easy to sanitize and corrosion-resistant.

-

Electrical Access: Ensure nearby power connections for models with UV or interlocking electronics.

-

-

🛠️ Maintenance Considerations

-

-

-

Daily Surface Cleaning with IPA or appropriate disinfectants

-

Weekly Filter Checks for HEPA-equipped models

-

Quarterly Calibration of interlock systems and timers

-

-

Maintaining these units is essential for long-term reliability and compliance.

✅ Final Thoughts

For cleanroom professionals—from engineers to maintenance staff—a pass through box is far more than a metal box with two doors. It’s a critical line of defense against contamination and inefficiencies.

When properly selected, installed, and maintained, pass boxes streamline operations, ensure safety, and help meet the most stringent international standards.

FAQs About Pass Through Boxes

Q1: Can a pass through box be customized for size or materials?

A: Yes! Manufacturers offer custom-built pass boxes to match your cleanroom layout, size, and cleanliness requirements.

Q2: Do I need a UV pass box or a dynamic pass box?

A: UV is ideal for bio-risk zones, while dynamic pass boxes are perfect for particle-sensitive environments like electronics or pharma.

Q3: What is the difference between a pass box and an air shower?

A: A pass box transfers materials; an air shower decontaminates personnel before entering a cleanroom.

Q4: Can pass boxes be installed into existing cleanrooms?

A: Absolutely. Retrofits are common—just ensure wall structure and utilities can support the unit.

Q5: What certifications should I look for in a pass box?

A: ISO 14644-1 compatibility, GMP readiness, and CE marking are industry standards.

Q6: How long does UV sterilization take inside a pass box?

A: Typically between 5–15 minutes, depending on lamp power and contamination level.

LAF passbox

LAF passbox