How to Solve Common Issues with Ceiling Laminar Flow Hoods

Discover effective solutions to common issues with ceiling laminar flow hoods, including uneven airflow, filter clogging, and noise. Ensure peak performance and compliance with expert maintenance tips.

1: Uneven Airflow

- Inspect the system for blockages and recalibrate airflow distribution.

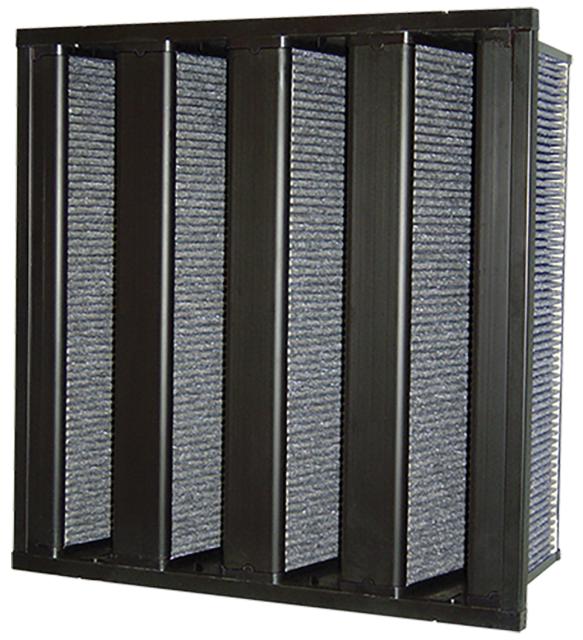

2: Filter Clogging

- Establish a routine filter replacement schedule and monitor usage hours.

3: Excessive Noise

- Verify that all mechanical components are properly aligned and lubricated.

Best Practices for Installation and Maintenance

Installation Tips:

- Site Preparation: Ensure the ceiling is clean and secure.

- Proper Alignment: Verify that the hood is level and integrated into the HVAC system.

- Testing: Conduct particle count and airflow tests post-installation.

Maintenance Schedule:

| Task | Frequency |

| Clean external surfaces | Weekly |

| Replace HEPA/ULPA filters | Every 1-3 years |

| Conduct airflow testing | Biannually |

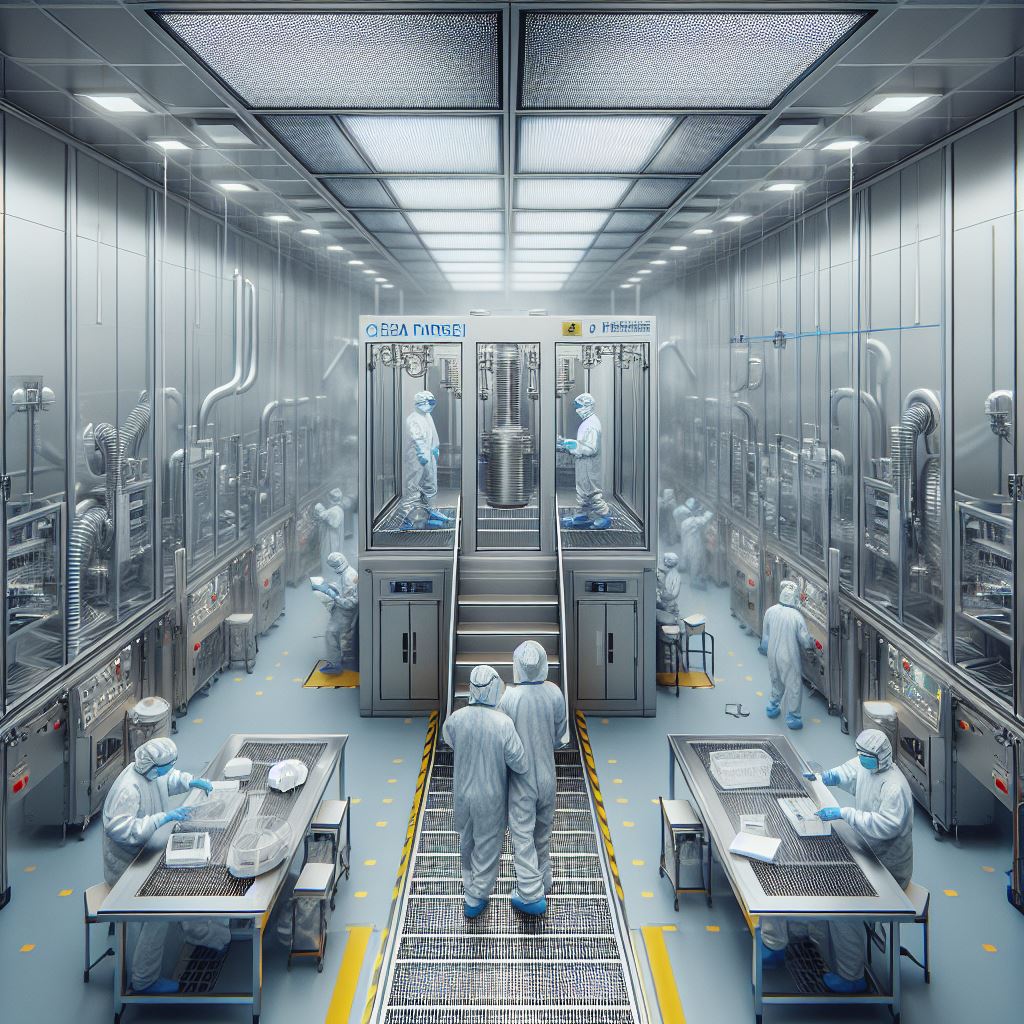

Case Study: Successful Cleanroom Design

Scenario: A pharmaceutical company faced challenges in maintaining ISO Class 5 standards. By integrating ceiling laminar flow hoods with smart airflow systems, they achieved a 40% reduction in contamination incidents and increased production efficiency.

Takeaway: Tailored solutions with advanced equipment make a significant impact on cleanroom performance.

FAQs About Ceiling Laminar Flow Hoods

1.How can I confirm my hood meets standards?

Request performance certifications and conduct independent particle count tests.

2.How long do filters last?

Typically, 1-3 years, depending on usage and environment.

3.Can ceiling hoods be retrofitted?

Yes, many systems offer flexible designs for integration into existing cleanrooms.

Conclusion

Ceiling laminar flow hoods are an indispensable asset for cleanroom professionals, Not only providing effective contamination control ,but also improving workspace efficiency. By selecting the right equipment, maintain it diligently, and leverage technological innovations, cleanroom managers can meet their operational goals while ensuring compliance.

LAF passbox

LAF passbox

pass through-flair

pass through-flair