Air Shower Maintenance

As a critical component in cleanroom operations, air showers play a vital role in maintaining product quality and process integrity by removing contaminants from personnel & cargos before they enter controlled environments. To ensure that air showers function at their highest efficiency, regular air shower maintenance is essential.

Here are some key maintenance practices :

- Filter Inspection and Replacement

The HEPA or ULPA filters built-in air showers are crucial for trapping airborne particles. Regularly inspect these filters for signs of clogging. HEPA Filters should be replaced per 6 to 12 months, the pre filter should be replaced per 3-6 months .but the exact replacement period may vary depending on usage intensity and cleanroom requirements. - Blower and Motor Maintenance

The blower and motor are the heart of the air shower system, responsible for generating the high-velocity air for effective decontamination. Regularly inspect the motor and ensure the blower is free from obstructions. Lubrication and tightening of components may be required to maintain optimal performance. - Nozzle Cleaning

The nozzles that direct air to personnel may become clogged, reducing the effectiveness &air capacity. Regularly clean the air nozzles is essential to maintain proper air velocity and direction, ensuring the system operates as designed. - Door Seal and Interlock System Check

The seals on the air shower doors are critical for preventing contaminants from entering the cleanroom. Regularly inspect these seals for damage or wear. Additionally, ensure the interlock system is functioning properly to prevent both doors from being opened simultaneously, which could compromise the cleanroom environment. - Routine System Testing

Conduct routine tests to verify that the air shower is performing according to specifications. This includes checking air velocity, particle removal efficiency, and overall system operation. Regular testing helps identify potential issues early, allowing for prompt resolution before they impact production.

By following these maintenance rerquests, you can extend the lifespan of air shower, minimize contamination risks, and ensure that the cleanroom operates efficiently and safely.

If you need further technical support or have any questions, don’t hesitate to reach out. We’re here to assist you.

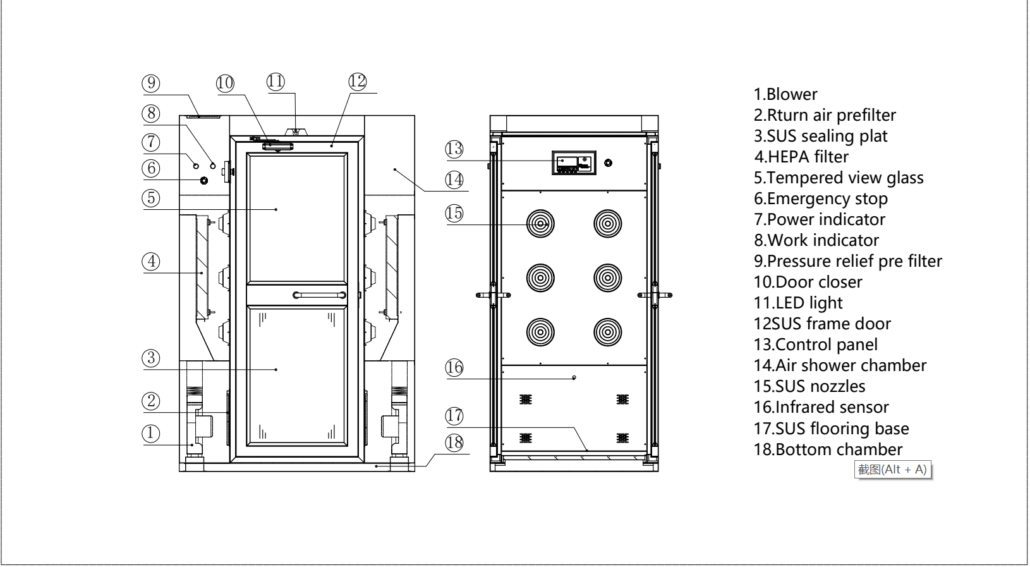

Air shower drawing