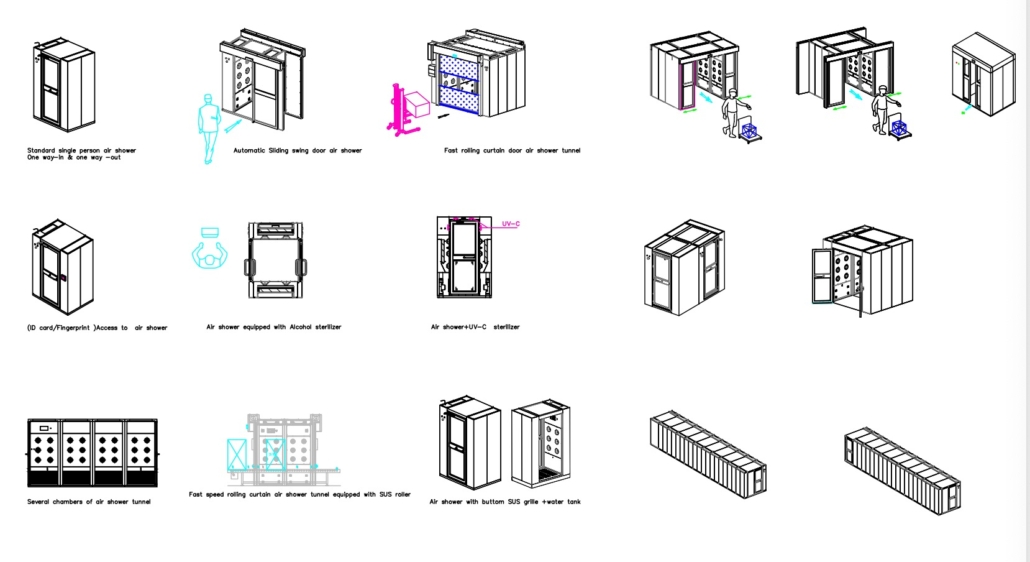

Air Shower Classifications

Air showers are essential equipment in cleanroom, designed to remove contaminants from personnel & materials before they enter or exit sensitive areas. These systems come in various configurations depending on industry needs, standards, and application requirements.

1. Classification by Design Style

Single-Person Air Shower

For individual use, these air showers decontaminate personnel entering the cleanroom.

Applications: Ideal for laboratories&small cleanroom facilities with limited personnel traffic.

Multiple-Person Air Shower

These air showers are designed to accommodate several personnel simultaneously, speeding up the decontamination process in high-traffic areas.

Applications:Commonly used in pharmaceutical&electronics manufacturing facilities, where large teams regularly access cleanrooms.

Tunnel Air Showers

Tunnel air showers are continuous, elongated air showers that allow multiple users to pass through simultaneously or sequentially without waiting for a reset between cycles.

Applications: Suitable for semiconductor or automotive manufacturing, where there is a constant flow of personnel and materials requiring passthrough.

L-Shaped and U-Shaped Air Showers

These air showers are designed in a compact, angular to fit tight spaces and offer flexible positioning options.

Applications: Frequently used in cleanrooms with space limitations.

2. Classification by Material

The material used in air shower construction is for durability, cleanliness, and resistance to environmental conditions. The right material choice can enhance longevity and cleanliness, particularly in industries with specific hygiene or chemical requirements.

Stainless Steel (SUS201 or 304 or 316)

Stainless steel air showers are highly durable, resistant to corrosion, and easy to clean, ideal for environments that require frequent sanitation.

Applications: Commonly used in pharmaceutical, food processing, and biotechnology industries, where hygiene and cleanliness are paramount.

Cold-Rolled Steel with Powder Coating

The air showers with powder coating are cost-effective and moderately durable. The powder coating adds protection against corrosion but may not be as long-lasting as stainless steel.

-Applications: Suitable for electronics and general manufacturing industries, where the need for chemical resistance is lower.

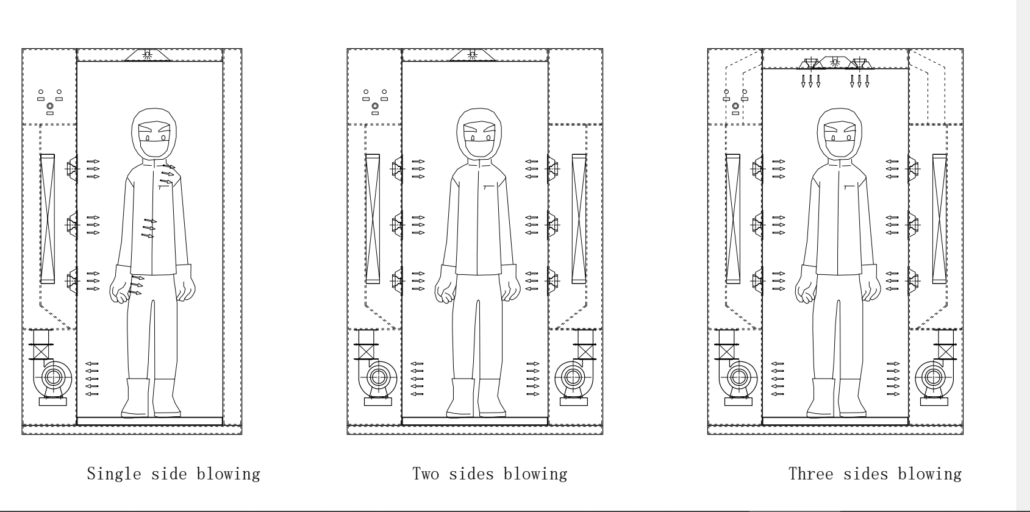

3. Classification by Blowing Types

4. Classification by Door Types

Air shower doors influence functionality, safety, and user experience. Different door types serve distinct needs, depending on traffic flow and cleanroom requirements.

Manual Swing Doors(single-swing or double-swing)

These are standard, doors that open and close by hands.

Advantages: Simple and cost-effective but prone to contamination from manual contact.

Applications: In low-traffic cleanrooms or where budget constraints exist.

Automatic Sliding Doors(single sliding or double sliding)

Sliding doors open and close automatically when triggered by motion sensors, offering a touch-free operation.

Advantages: These doors are ideal for high-traffic cleanrooms as they reduce contamination risks and improve workflow efficiency.

Applications: Commonly used in pharmaceutical and electronics manufacturing industries.

IC Card Access +fingerprint Air Shower Doors

IC (Integrated Circuit) card access doors allow personnel to enter and exit air showers by an authorized card /fingerprint. The card contains embedded information, which the system reads to grant or deny access.

Applications:Biotechnology and Medical Device Manufacturing,Pharmaceutical Research and Development,Defense and Aerospace

Fast rolling PVC curtain

Air showers with fast rolling PVC curtain doors are lightweight and chemically resistant, making them ideal for environments with corrosive chemicals.

Applications: In chemical processing plants and laboratories handling volatile substances.

5. Classification by passing through

Air shower pass through requirement is an important consideration depending on personnel or material needs.

Personnel Air Showers

These are compact air showers designed to accommodate a single person at a time.

Applications: Ideal for low-traffic environments or cleanrooms with limited space, such as research labs and small production facilities.

Material Transfer Air Showers for carts or trolley

Specifically for materials, carts, or equipment pass through, these showers often feature wider chambers and are optimized for bulk decontamination.

Applications: Essential in electronics, automotive, and medical device manufacturing industries where machinery and tools need to be cleaned before entry.

6. Classification by Function

Air showers can also be categorized based on their specific functions, whether they’re designed solely for basic decontamination or offer additional, customized features.

Explosion-Proof Air Showers

Designed for use in hazardous environments where volatile chemicals or gases are present, these air showers are reinforced to prevent sparks or explosions.

Applications: Common in chemical processing plants, oil refineries, and pharmaceutical facilities handling dangerous materials.

Hybrid Air Showers (Dual-Purpose)

The air showers combine personnel decontamination with material transfer, offering dual functionality in one system.

Applications: Be Useful in industries like semiconductor or pharmaceutical manufacturing, where both personnel and materials need to be decontaminated simultaneously.

Integrated Sole Cleaning Function

Some air showers are built-in automatic sole cleaners, which clean the sole of personnel as they enter or exit the cleanroom. This is important for environments where foot-borne contaminants are a concern.

Applications: Typically in industries like food processing, pharmaceutical, and medical device manufacturing.

Conclusion

Selecting the right air shower for your cleanroom is essential to maintaining cleanliness, operate efficiency, and compliance with industry standards. Whether you need personnel air shower, or a cargos air shower with added features like sole cleaning or explosion-proof function, Hope these classifications will help you choose the most suitable one for your specific needs.

If you’re planning to install or upgrade your cleanroom air shower system, or need advice on a custom solution, contact us freely for tailored recommendations that fit your cleanroom operations.