Air shower tunnel,a custom prolong air shower for workers to pass through ,is an essential decontamination system in industries requiring ultra-clean environments, such as pharmaceuticals, electronics, and food processing. These tunnels use high-velocity HEPA-filtered air to remove dust and contaminants from personnel before they enter a cleanroom.

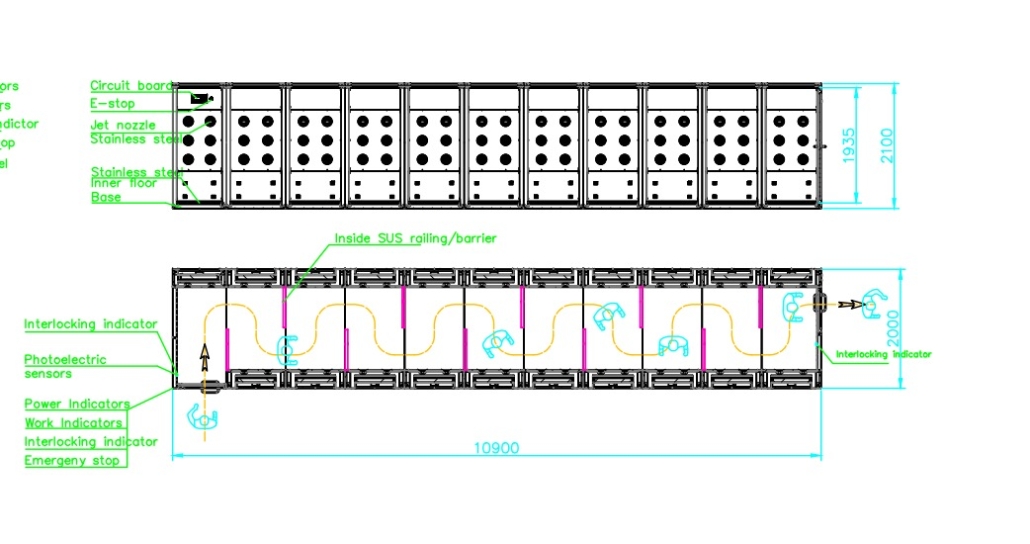

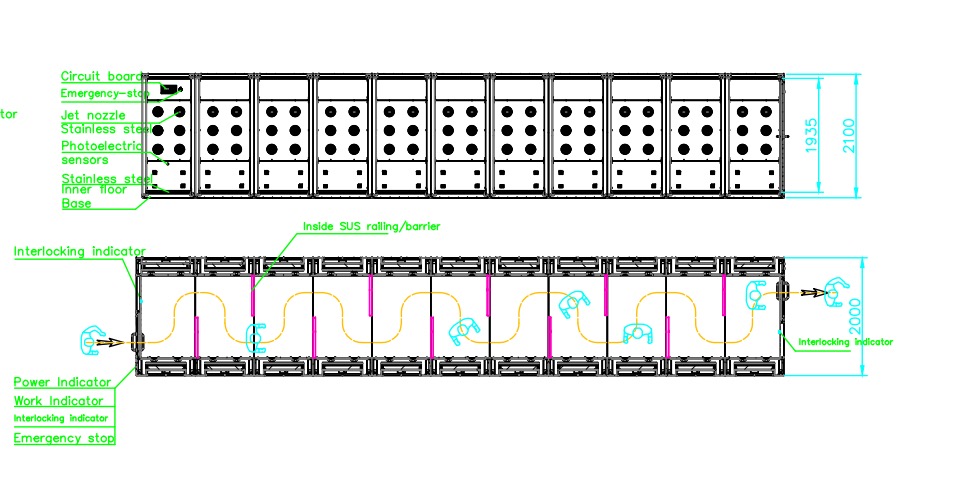

To enhance cleaning efficiency, modern air shower tunnels include barriers or rails, forcing personnel to follow an S-turn pathway for extended decontamination exposure.

Understanding Air Shower Tunnel Designs

| Type | Design | Best For | Pros | Cons |

| L-Shape Air Shower | 90-degree turnwith built-in rails forcing an S-turn | Space-constrained areas | Space-efficient, adaptable | May slow down workflow |

| S-Shape Air Shower | Zigzag pathwaywith built-in rails forcing an S-turn | High-contamination risk areas | Superior decontamination, effective in crowded environments | Requires more space |

Built-in barriers or rails

- Built-in barriers or railsforcing personnel into an S-turn.

- Ensures workers cannot walk straight through, maximizing air exposure.

- Ideal for industries with strict contamination control requirements.

Key Features of Air Shower Tunnels

✅ HEPA/ULPA Filtration

- Captures 99% of particlesas small as 0.3 microns.

✅ High-Velocity Air Jets

- Air speeds of 18-30 m/sremove dust and contaminants efficiently.

✅ Interlocking Doors for Contamination Control

- Prevents cross-contamination by allowing only one door to open at a time.

✅ S-Turn Barriers for Extended Exposure

- Built-in railsor obstacles force workers to take an S-turn, increasing decontamination time.

✅ Modular & Customizable Design

- Available in stainless steel, powder-coated steel, and other materials based on industry needs.

✅ Touch-Free Operation

- Motion sensorsactivate the air shower when a person enters, reducing manual contact.

If you have anhy new inquiry or custom air shower tunnel requirement ,pls contact us freely : info@flairequip.com